Understanding What Defines a High Quality Rolling Paper

How paper thickness affects ignition, burn rate, and smoke density

Thickness controls how quickly a rolling paper catches fire, how evenly it continues to burn, and how much smoke it produces. Thicker papers ignite faster but tend to deliver heavier smoke and stronger paper taste, which may not appeal to those who prefer a cleaner session. Thinner papers support controlled ignition, slower burn, and reduced interference with the natural aroma of the material being rolled. Many experienced users in India now compare GSM ratings to understand how thickness aligns with their preferred burn style.

Why material purity matters for cleaner combustion and fewer residues

Papers made from pure plant fibers and free from unnecessary chemical treatments usually offer a cleaner burn, especially for buyers searching for rolling paper online india who prioritise smooth combustion and minimal residue. Impure materials often create uneven burns, harsh aftertastes, and visible ash residues, which can significantly affect overall satisfaction for regular users. Purity becomes a measurable factor when evaluating premium rolling papers because it impacts both the sensory experience and the inhalation quality, making brands that focus on natural fibers more appealing. Platforms like https://litaf.in/ showcase options that emphasise clean composition and trustworthy sourcing, helping buyers make informed choices. Brands that disclose fiber origins, maintain transparent manufacturing practices, and avoid fillers or industrial additives generally earn higher trust among regular buyers.

How porosity influences airflow and temperature control

Porosity defines how much air passes through the paper during a session, directly shaping temperature, burn speed, and smoothness. Papers with higher porosity burn faster because more oxygen fuels the flame, while low porosity papers burn slower and maintain stable temperatures. Buyers often compare porosity to match their desired pace and material density, especially when rolling blends that require precise airflow to maintain an even burn.

Role of natural gum lines in maintaining structural stability

The gum line is responsible for keeping a roll intact from start to finish. Natural gum sources such as acacia gum provide reliable sealing without altering taste. A high quality gum line adheres firmly even in warm Indian climates, preventing unraveling and maintaining structural uniformity. Poor quality gum lines either overstick or fail to seal, which interrupts burn consistency and overall enjoyment.

Impact of bleaching and chemical treatments on taste and safety

Bleached rolling papers often appear whiter but may introduce chemical residues that influence both taste and burn behavior. Many buyers now look for unbleached or chlorine free labels to avoid additives that can affect combustion safety. Chemical treatments sometimes alter paper strength and aroma, making them a consideration for those seeking a natural experience. Transparent sourcing and certifications help buyers determine which products maintain purity without compromising performance.

Rolling Paper Materials Available in India and Their Performance Differences

Wood pulp papers and their durability profile

Wood pulp papers remain common in India because they are sturdy, easy to roll, and forgiving for beginners. Their durability supports consistent shaping, though they often burn faster than natural alternatives. These papers can introduce mild flavor, making them suitable for users who prioritize strength and handling over ultra neutral taste.

Hemp papers and their neutral flavor delivery

Hemp based papers are valued for their balance of strength, slow burn, and neutral flavor output. They maintain structure well and produce minimal paper taste, allowing the rolled material to take center stage. Hemp fibers also appeal to buyers seeking eco friendly choices due to their renewable, low impact cultivation.

Rice papers and their ultra slow burn characteristics

Rice papers are thin, lightweight, and favored for their delicate, almost invisible presence during use. Their slow burn and low smoke density support a smooth experience, though they require careful rolling due to their fragile texture. Many experienced rollers choose rice papers when flavor purity is the top priority.

Flax fibers and their lightweight, smooth finish

Flax based papers offer a clean, smooth texture and moderate burn speed suitable for both beginners and seasoned users. These papers bring a lightly structured feel without adding harshness or noticeable taste. Flax fibers provide natural stability, making them dependable for various rolling styles.

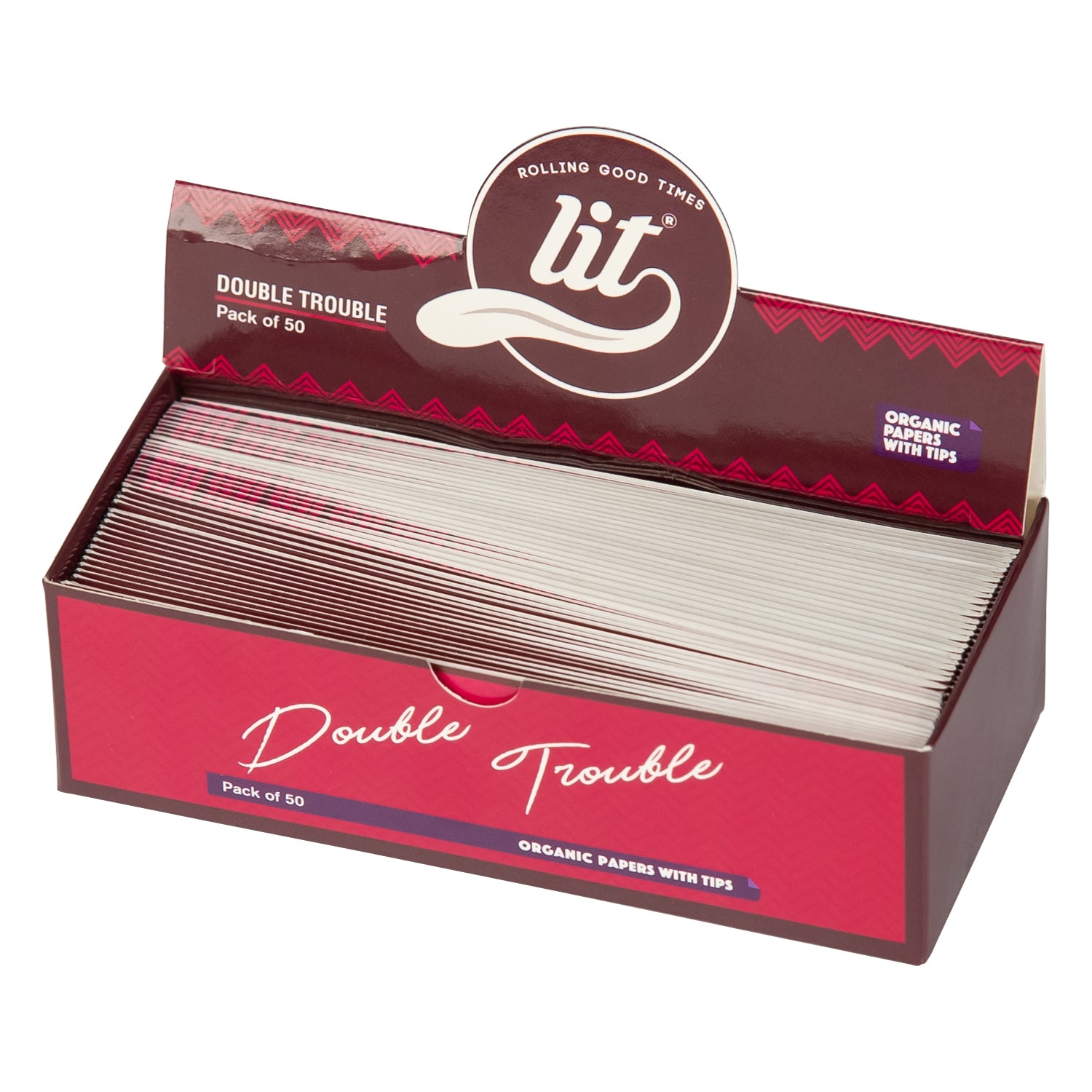

Unbleached and organic variants with verified sustainability

Unbleached papers avoid chlorine and other whitening agents, giving them a natural brown tone and cleaner combustion profile. Organic options elevate this further by ensuring the plant fibers come from chemical free cultivation. Buyers who prioritize sustainability often choose these variants because they support clean burns and reduced environmental impact.

Flavored papers and how additives influence the overall session

Flavored papers introduce fruit, mint, or dessert inspired notes through food grade additives. These papers enhance aroma but may slightly alter temperature and burn behavior depending on the flavoring technique. They remain popular among casual users who prioritize novelty and sensory customization.

Sizes, Formats, and Use Cases Buyers Commonly Compare in 2026

Single wide papers for compact rolls

Single wide papers remain a preferred choice for compact, discreet rolls because they limit paper usage and support shorter sessions. These papers suit light users and those who prefer minimal material consumption while maintaining manageable airflow.

1¼ size for balanced airflow and control

The 1¼ size provides a well balanced format that blends ease of rolling with stable airflow. This size has become a standard for many Indian buyers because it accommodates moderate material quantities and consistently delivers an even burn without overwhelming smoke density.

King size for longer sessions

King size papers support extended sessions and higher material capacity. They work well when sharing or when a slower, lengthier experience is desired. Their larger surface requires more rolling skill, making them popular among confident users.

King size slim for experienced rollers seeking low paper taste

King size slim papers offer the length of king size formats with reduced width, lowering paper to material ratio. This format supports clean flavor expression and slow, controlled burn patterns. Experienced users appreciate the precision required to roll these papers evenly.

Pre rolled cones for convenience and consistent shape

Pre rolled cones eliminate manual shaping and provide consistent airflow channels. They are ideal for beginners, buyers who prefer convenience, and those seeking uniform burns without technical rolling effort. The cone structure optimizes airflow, reducing hot spots and tunneling.

Paper rolls for customizable lengths

Paper rolls offer complete control over length and capacity, allowing users to create compact or extended formats as needed. This flexibility appeals to buyers who prefer custom sizing or who mix different materials that require specific airflow and density adjustments.

Decision Factors Buyers Evaluate Before Choosing a Rolling Paper

Burn speed suitability for the material being rolled

Burn speed determines how well a paper matches the density, moisture level, and texture of the material being used. Slow burning papers work well with dry, finely ground material, while faster burning papers can support denser or slightly moist blends. Matching burn rate to material ensures smooth combustion without canoeing or frequent relights, which many buyers now evaluate before choosing any paper.

Taste neutrality and how composition alters flavor

Taste neutrality depends heavily on fiber source, processing methods, and the presence or absence of chemical treatments. Plant fibers like hemp or rice offer clean flavor profiles, allowing the material’s aroma to remain dominant. Papers that introduce noticeable taste often come from thicker fibers or artificial additives, which can overshadow natural notes. Buyers who prioritise full flavor expression look for papers advertised as low taste or neutral profile.

Ease of rolling for beginners and advanced users

Ease of rolling is influenced by texture, rigidity, surface grip, and paper thickness. Beginners generally find moderately thick papers easier because they maintain shape during tucking and folding. Experienced users may opt for ultra thin papers that require precision but ensure cleaner sessions. Texture also plays a role because lightly gripped surfaces help hold the material in place during shaping.

Tear resistance and structural strength under humidity

High humidity affects rolling papers in many Indian regions, making tear resistance a key decision factor. Papers with balanced fiber density maintain strength without becoming brittle or overly soft. A paper that withstands humidity during rolling and burning prevents breaks, uneven airflow, and wasted material. Premium papers often undergo moisture testing to ensure predictable structural performance.

Price tiers, value assessment, and quantity per pack

Price ranges differ significantly based on fiber source, production quality, and brand positioning. Value assessment focuses not only on cost but on per-sheet performance, burn consistency, and overall user satisfaction. Buyers compare sheet count, brand reputation, and durability before selecting a paper that matches their budget and expectations.

Brand transparency, material sourcing, and third party certifications

Transparency has become a deciding factor for many regular users because it reflects the brand’s commitment to safety and quality. Clear sourcing, disclosure of fiber types, and verifiable certifications help buyers choose products that maintain purity. Certifications related to sustainability or chemical free processing also guide informed choices.

User experience indicators like real world burn tests and sensory feedback

User feedback, sensory reviews, and real world burn tests provide practical insights that go beyond manufacturer claims. Burn tests often highlight consistency, ash behaviour, smoke density, and paper taste. Buyers rely on these observations to confirm whether a paper performs reliably across different conditions and usage styles.

Common Buyer Mistakes and How to Avoid Them

Selecting overly thick papers that interfere with flavor

Thick papers impart stronger paper taste and produce heavier smoke, which can overpower the natural character of the material. Choosing paper thickness purely for rolling ease can compromise flavor purity. Assessing GSM and opting for balanced thickness helps avoid this issue.

Ignoring chemical treatments that affect combustion

Some papers undergo whitening or strengthening treatments that introduce unwanted chemicals. These additives influence burn temperature, aroma, and combustion smoothness. Checking labels for chlorine free or unbleached markers reduces exposure to chemically altered papers.

Focusing only on price instead of burn quality

Budget oriented decisions may overlook consistency, material purity, and long term satisfaction. Low cost papers often burn unevenly or tear easily, leading to repeat purchases. Evaluating value instead of absolute price helps buyers choose more dependable options.

Not examining the gum line for natural adhesives

The gum line determines how well a roll maintains structure throughout use. Non natural adhesives may affect taste or fail under humidity. Selecting papers with acacia or other natural gums ensures secure sealing and stable airflow.

Overlooking product authenticity and counterfeit risks

Counterfeit papers appear frequently on online marketplaces and often contain inferior materials. Authenticity checks include verifying seller ratings, scanning brand tags, or comparing packaging details with official product listings. Authentic papers ensure safety, consistency, and reliable burn quality.

Skipping user reviews that highlight real performance issues

User reviews often reveal factors not mentioned in product descriptions such as burn irregularities, gum line failures, or unexpected tastes. Ignoring these insights leads to repeated buying mistakes. Reading verified reviews helps buyers identify stable performers.

Leading Rolling Paper Brands in India Worth Considering for 2026

Premium hemp based manufacturers known for consistent slow burn

Hemp based brands have gained popularity due to their controlled burn speed, structural strength, and neutral taste. These manufacturers use refined fibers and minimal processing to produce papers suited for both novice and advanced users. Their consistency appeals to buyers who prioritise predictable performance.

Organic and unbleached paper brands prioritizing purity

Brands that focus on unbleached, organic materials attract users who value clean combustion and minimal processing. These papers avoid chlorine and synthetic whiteners, helping preserve natural color and fiber integrity. They align well with sustainability focused buyers.

Budget friendly brands suitable for everyday use

Users who roll frequently often prefer affordable yet dependable papers that balance durability with acceptable burn quality. Budget friendly brands offer predictable performance without premium pricing. These papers serve casual and daily users seeking steady value.

Specialty flavored and artisanal micro brands gaining popularity

Flavored and small batch artisanal brands appeal to those looking for unique profiles, creative sensory experiences, and novelty. These brands often use food grade flavoring and produce limited edition batches that enhance aroma and enjoyment. Their emergence reflects growing interest in personalized rolling experiences.

How to verify authenticity across online marketplaces

Authenticity checks safeguard buyers from imitation products that compromise performance. Reliable methods include purchasing from verified sellers, inspecting packaging for holograms or batch codes, and comparing product details with official brand listings. Verifying origin and seller reputation reduces the chances of receiving substandard or counterfeit items.

How to Store Rolling Papers for Longevity and Optimal Performance

Controlling humidity to prevent curling and tearing

Humidity is one of the most common causes of curling, softening, or tearing in rolling papers, especially in regions with fluctuating climate. Excess moisture weakens fiber structure and leads to uneven burning during use. Keeping papers in a dry, controlled environment helps maintain their original texture and strength. Buyers often use small pouches or storage boxes with moisture control to protect papers from seasonal humidity variations.

Keeping papers flat to protect structural integrity

Rolling papers maintain optimal performance when stored flat because bending creates weak points along the fibers. Curved or folded papers make rolling difficult and can lead to inconsistent airflow. A flat, rigid surface such as a card sleeve or dedicated case reduces the chances of warping and helps retain original sheet alignment for clean, predictable rolling.

Preserving gum line quality by avoiding heat and direct sunlight

The gum line loses stickiness when exposed to prolonged heat, sunlight, or temperature shifts. Natural gums like acacia require stable conditions to remain effective. Keeping papers away from windows, car dashboards, or areas with high heat prevents premature drying of the adhesive. Storing them in a shaded, temperate space ensures the gum line retains its sealing strength and reliability.

Using storage sleeves or airtight pouches for long term use

For buyers who store multiple varieties or purchase papers in bulk, airtight pouches and rigid sleeves help maintain freshness over extended periods. Airtight containers protect fibers from dust, humidity, and accidental bends while preserving the gum line. Many experienced users invest in compact protective cases that safeguard papers during travel or daily carry, ensuring consistent performance whenever needed.

Frequently Asked Questions on Choosing Rolling Papers in India

Which rolling paper material offers the cleanest flavor

Rice and hemp papers typically provide the cleanest flavor because they burn with minimal smoke and introduce very little paper taste. Unbleached variants further enhance neutrality by avoiding chemical agents.

What size should a beginner choose

Beginners often find the 1¼ size simplest to roll because it offers a balanced width and manageable surface area. It provides steady airflow without the precision required for ultra thin or extra long papers.

Do flavored papers affect the burn quality

Flavored papers may slightly influence burn temperature and smoke density depending on the type of additive used. High quality flavored papers apply food grade coatings designed to maintain stable burn performance.

How can I identify counterfeit rolling papers online

Counterfeits often lack proper packaging details, batch codes, or consistent gum lines. Purchasing from verified sellers, inspecting brand marks, and comparing product images with official listings help ensure authenticity.

Why do some papers canoe or burn unevenly

Uneven burning can happen due to material density, improper rolling technique, or papers with inconsistent fiber distribution. Choosing papers with reliable porosity and practicing even packing helps prevent canoeing.

Are unbleached papers always better

Unbleached papers avoid chlorine and whitening agents, making them appealing for those seeking natural options. Whether they are better depends on the user’s priorities regarding flavor neutrality, sustainability, and purity.

What factors matter most for long term storage

Humidity control, flat placement, and protection from heat are the primary factors affecting longevity. Airtight or rigid storage solutions help preserve both fiber strength and gum adhesion over time.