It All Begins with Grinding

ust like any other cannabis product, the journey of making pre-rolls commences with the cannabis plant, specifically the cured flower. The versatility of the plant allows for various products, and when it comes to pre-rolls, there are numerous factors to consider before rolling up.

Proper drying and curing of the flower are essential, followed by grinding it into the right-sized particles and sifting to eliminate any unwanted material such as stems or leafy fragments. Only after completing these steps can you move on to filling, sealing, and packaging your final product. This is precisely why we've crafted this pre-roll manufacturing guide — to provide a detailed breakdown of how to produce pre-rolls, scale up your manufacturing process, and innovate new pre-roll products!

Starting with the Flower

When preparing cannabis flower for pre-rolls, it's crucial to preserve its integrity. High rpm grinding machines like blenders or food processors can generate heat, leading to the flower becoming pulverized into dust, degrading cannabinoids and terpenes. Additionally, uneven particle sizes can result, affecting the burn and consistency of pre-rolls. To maintain quality, opt for low rpm grinders with high torque and screens for consistent particle size.

Sifting Machines

Sifting ensures uniform particle distribution and removes unwanted material like stems, enhancing pre-roll quality. Over-sifting should be avoided to prevent trichome separation. Industrial sifters offer quality control by removing stems and small particles, improving the smoking experience and preventing clogs.

Pro Tips

- Kief Collection: Collect kief post-sifting and mix it back with sifted flower for consistent potency.

- Drying/Curing: After grinding and sifting, allow the material to dry/cure again to prevent stickiness, which can hinder pre-roll assembly.

Pre-Roll Manufacturing

Efficient pre-roll production requires attention to detail at every stage. Despite common myths, the size of the cartridge doesn't solely determine production speed. Smaller machines with multiple trays often offer better throughput and prevent bottlenecks in the production line.

Manufacturing Hemp Wrap Blunts at Scale

Storage of hemp-based papers is crucial due to their sensitivity to temperature and moisture. Maintaining optimal humidity levels with a humidor prevents papers from becoming brittle or moldy, ensuring quality and compliance.

Pre-Roll Machines and Accessories

Accessories like metering trays and work in progress trays enhance efficiency and consistency in pre-roll production. Metering trays ensure precise filling, crucial for compliance, while work in progress trays facilitate organized pre-roll storage.

3 Ways to Seal a Pre-Roll

- Twist

- Dutch Crown

- Fill and Fold Machine

Automated Pre-Roll Machines

Automated machines offer advantages like consistent quality, reduced labor costs, and exportable production data. However, they require careful maintenance and control over flower quality, moisture content, and temperature.

Pros and Cons of Automated Machinery

While automated machines streamline production and offer uniformity, they entail high setup costs and limited flexibility in processing sticky flower. Incorporating automation depends on production goals and capabilities.

Manufacturing Infused Pre-Rolls

Automation in infusion processes ensures consistent quality in mass production. Handcrafted options offer flexibility but are time-intensive.

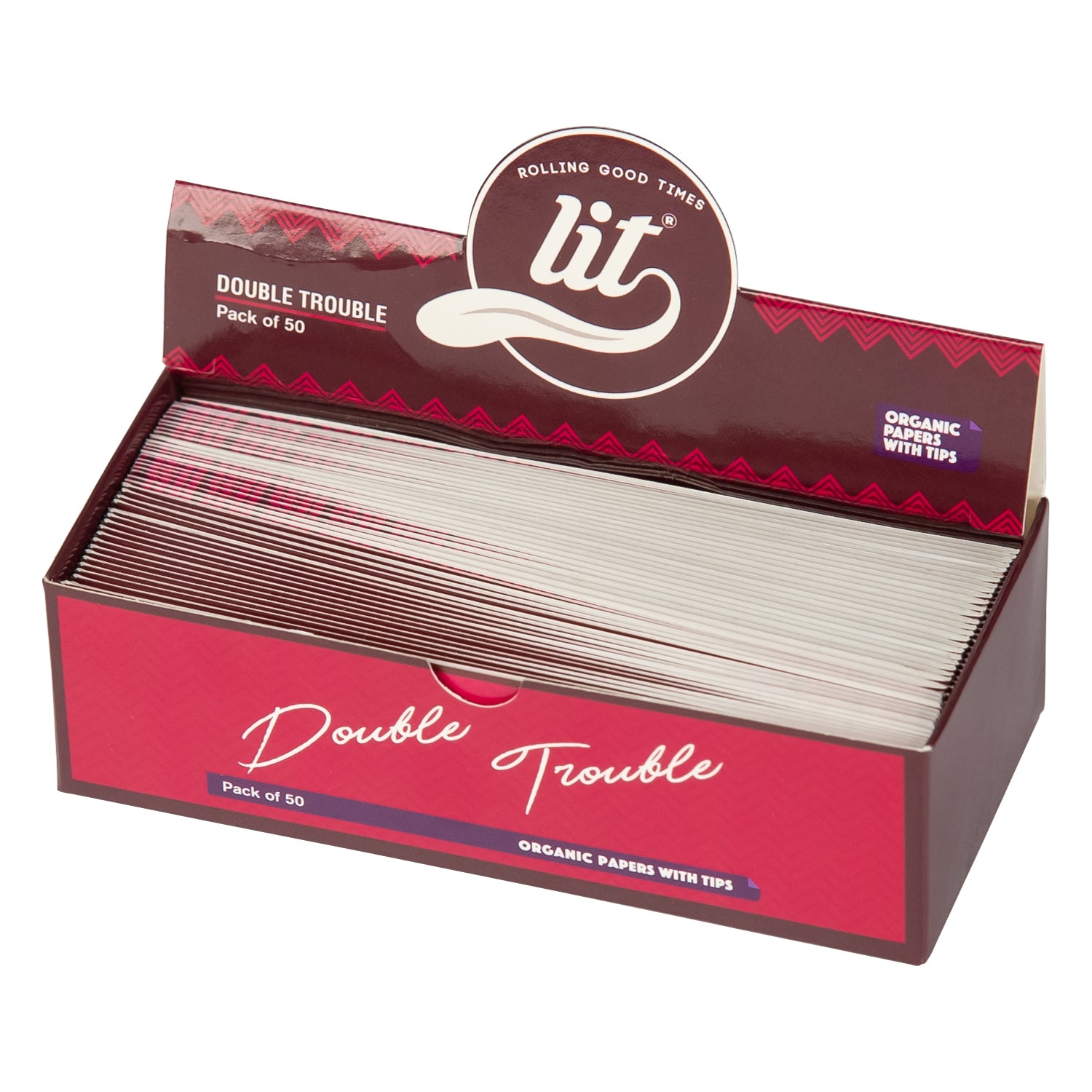

Packaging

Packaging plays a crucial role in brand identity and differentiation. Customizable options cater to various branding needs, from affordable to luxurious, eco-friendly, or child-resistant.

Final Inspection

Before distribution, thorough inspection ensures compliance and product quality. Weighing pre-rolls and visual checks ensure accurate weights and pristine appearance.

Containers & Wraps

Choosing the right packaging reflects brand values and attracts customers. Customizable options cater to diverse branding needs, ensuring a memorable consumer experience. Branding and design services are available to create impactful packaging.